منتجات الرغوة البولي يوريثين متعددة الاستخدامات ومفيدة في العديد من الصناعات. يتم تفاعل ثنائي إيزوسيانات مع مجموعة متنوعة من البوليوهول لإنتاج رغوات صلبة ومرنة تتميز بخصائص عزل استثنائية. تجد منتجات الرغوة البولي يوريثين استخدامًا في مجموعة متنوعة من الصناعات، من البناء إلى السيارات وصناعة الأثاث أو التعبئة والتغليف. سيركز هذا المقال على فوائد منتجات الرغوة البولي يوريثين لعزل المنازل، وسيتعمق في اكتشاف المنتجات المناسبة ذات الجودة الصناعية العالية واختيارها الصحيح حتى في المشاريع التي يقوم بها الهواة باستخدام Polyurethanefoamsydney، كما سيقدم دراسات حديثة حول استخدام الحالات في البناء الصديق للبيئة باستخدام تقنية البولي يوريثين المقاومة للرطوبة، وكيف تسهم صناعة السيارات في تطوير خط منتجات جديد مبتكر من خلال PUFOAM_ADAR_Sealants.

من المرجح أنك قد رأيت هذه المنتجات واعتقاد أن لها كفاءة عالية كعزل للمنزل، فهي اقتصادية && توفر الطاقة، لذا تستخدم مادة البولي يوريثين لتلبية مثل هذه الاحتياجات. وهذا يتضمن عزل الرغوة المغلقة بالرش، والذي يعتبر ممتازًا لسد الهواء في الجدران والسقوف أو阁 الأسطح. في أشهر الشتاء، تعمل على منع فقدان الحرارة وكذلك في الصيف - ومنع زيادة الحرارة الناتجة عن أشعة الشمس عبر النوافذ، مما يساعد في تقليل استهلاكك للطاقة وبالتالي تقليل ديونك المباشرة! بالإضافة إلى ذلك، يمكن أن تساعد منتجات الرغوة البولي يوريثين في تحسين جودة الهواء الداخلي عن طريق تقليل كمية حبوب اللقاح والغبار والملوثات الخارجية التي تدخل منازلنا. هذا المقاومة للفطريات والعفن والحشرات تضيف قيمة أكبر بحماية الصحة وكذلك منع الأضرار الهيكلية مع مرور الوقت.

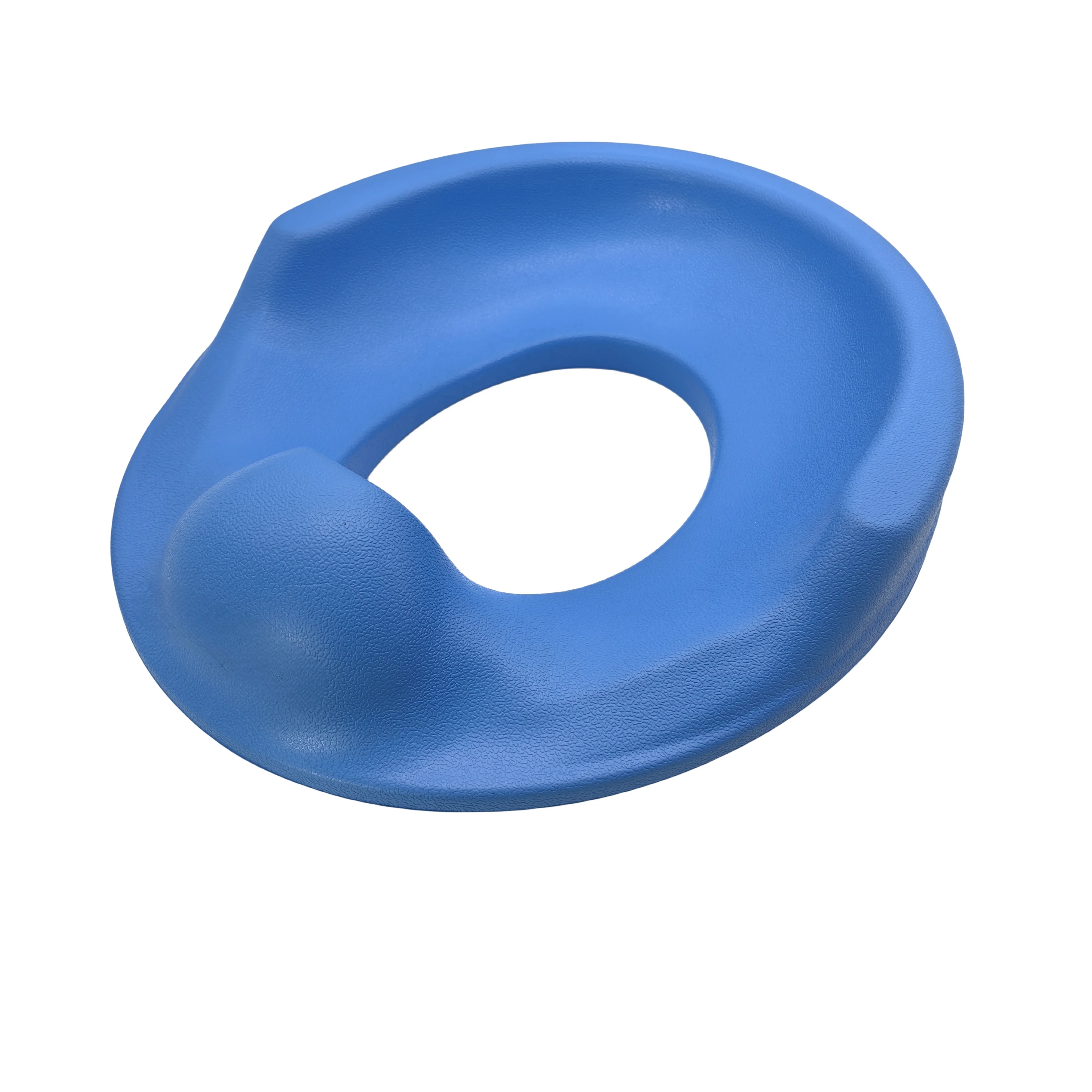

تُستخدم منتجات الرغوة البولي يوريثين في العديد من التطبيقات الصناعية الثقيلة، مثل العزل والتنعيم وامتصاص الاهتزاز. هناك بعض عناصر الرغوة البولي يوريثين التي يمكن أن تحسن أداء المهام مثل ألواح العزل الصلبة، الوسائد المرنة وكذلك الرغوة الم啧رة. تُستخدم ألواح العزل الصلبة لعزل المباني المعدنية، ومستودعات التبريد، وغيرها من الهياكل التي تتطلب مقاومة حرارية عالية مع حاجز بخار مقاوم. من المشاريع الذاتية إلى التطبيقات الصناعية، يمكن استخدام الوسائد المرنة لتوفير الراحة للمركبات والأثاث بينما تحتفظ الرغوة الم啧رة بسمعتها في سد تسرب الهواء في المباني التجارية الكبيرة.

اتخاذ قرارات مدروسة يجب أن يكون أولوية قصوى للأشخاص الذين يخططون لتنفيذ مشاريع DIY التي تتضمن منتجات رغوة البولي يوريثين. النقطة الابتدائية هي نوع الرغوة، رغوة مرنة أو غير مرنة. افحص كثافة الرغوة التي ستؤثر في النهاية على القوة والديمومة. الرغوات ذات الكثافة الأعلى ستمد أكثر وتكون أقوى من تلك ذات الكثافات المنخفضة. معدل التفاعل/زمن التصلب/أو قياسات التصلب لها أهميتها أيضًا من حيث المدة التي سيستغرقها قدرة طحن الرغوة. وأخيرًا، تذكر اتخاذ جميع الاحتياطات اللازمة عند العمل مع الرغوة - ارتدي الحماية المناسبة واعمل في منطقة جيدة التهوية.

تُستخدم منتجات الرغوة البوليويرثينية بشكل متزايد في أشكال الممارسات المستدامة للبناء الأخضر، وذلك بسبب خصائص العزل الحراري المتأصلة فيها (الخلايا المفتوحة والمغلقة) وكذلك فوائد الكفاءة الطاقوية. عزل الرغوة البوليويرثينية المُرشَّحة في مكانها، والرغوة البوليويرثينية ذات الأساس البيولوجي والعوازل الهيكلية المصنوعة من نفس المادة (SIPs) هي بعض من المنتجات الابتكارية التي تدخل في مبادرات البناء الأخضر. يمكن أن يكون عزل الرغوة البوليويرثينية منتجاً يُرشح في مكانه لسد تسربات الهواء في الجدران والأسطح، أو قد يكون على شكل رغوة بيولوجية تُصنع من مواد قابلة للتجديد مثل فول الصويا وزيت الخروع. نظرًا لأن ألواح العزل الهيكلية تتكون من طبقتين من الألواح الهيكلية مع رغوة البوليويرثين بينهما، فإنها تخلق منازل معزولة جيدًا مما يساعد في توفير تكاليف التدفئة والتبريد.

رغوة البوليويرثين: كيف يُحدث هذا المواد ثورة في صناعة السيارات

تعيش صناعة السيارات تحولاً ملحوظاً في التصميم والتصنيع باستخدام منتجات الرغوة البولي يوريثين. تُستخدم هذه المنتجات المغلفة بشكل صلب كأجزاء من وسائد المقاعد،及 رؤوس الدعامات، الأبواب واللوحات القياسيّة. يُفضل استخدام منتجات الرغوة البولي يوريثين في قطاع السيارات لأنها خفيفة الوزن، قوية ويمكن تخصيصها حسب الحاجة. تسهم هذه الخصائص في تحسين كفاءة استهلاك الوقود وتعزيز سلامة الاصطدام في المركبات. يمكن للمصنعين السيارات أن يكونوا أكثر تميزًا وإبداعًا في تصاميمهم بفضل مرونة منتجات الرغوة البولي يوريثين. مع انتشار السيارات الكهربائية والمركبات ذاتية القيادة، ستلعب منتجات الرغوة البولي يوريثين دورًا أساسيًا في تشكيل مستقبل صناعة السيارات لسنوات عديدة قادمة.

بالمجمل، فإن رغوة البولي يوريثين هي واحدة من أهم المواد في المجال. فوائد هذه المنتجات لعزل المنازل السكنية، فائدتها في التطبيقات الصناعية عالية الأداء، كيفية تحديد المنتجات المناسبة لمشروعك اليدوي وحتى أمثلة على مناهج البناء البيئي باستخدامها تشير إلى خصائصها كمنتج متعدد الاستخدامات يقدم حلولًا موفرة للطاقة ذات إمكانات وفيرة لتوفير التكلفة، مما يعزز سبب تميز منتجات رغوة البولي يوريثين وإنشائها معايير جديدة حول المرونة مقابل الأداء، مما يضمن لها دائمًا التفوق على المنافسة. نظرًا للمخاطر المرتبطة بهذه المواد، يجب التعامل معها بحذر واتخاذ احتياطات السلامة اللازمة.

تأسست شركة تشينغهه رونغهي لأنابيب المطاط المحدودة في عام 2015 وهي مؤسسة متخصصة في تصنيع المنتجات المطاطية والمكونات البلاستيكية. المنتجات الرئيسية: منتجات الرغوة البوليويرثين، منتجات بلاستيكية، أجزاء مطاطية مصنوعة بالقوالب وختمات الإغلاق. يتم شحن المنتجات إلى أوروبا وأمريكا وإفريقيا وجنوب شرق آسيا وغيرها من الدول.

نراقب منتجات الرغوة البولي يوريثين كل عملية إنتاجية لضمان توفر متطلبات التوريد المناسبة بالنسبة للوقت، الجودة والكمية. تركيزنا هو تقديم حلول كفiciente ومخصصة لمنتجات الرغوة PU بما في ذلك منتجات المطاط ومنتجات البلاستيك التي تلبي متطلباتك الفردية. يمكنك أن تكون متأكدًا من خدمة ذات جودة عالية لأن لدينا نظام دعم ما بعد البيع يتضمن مساعدة فردية.

لا يهم إذا كان الأمر يتعلق برغوة الـ PU أو منتجات المطاط، يمكن لمنتجات رغوة البولي يوريثين أن تكون قوية ومتينة مع كونها خفيفة الوزن. كما يمكن أن تكون مقاومة للحرارة، مقاومة للبرودة ولديها عمر خدمة طويل. سatisfy مجموعة منتجات Ronghe جميع احتياجاتك بغض النظر عن نوع منتجات الـ PU مثل أجزاء المطاط أو المكونات البلاستيكية التي تحتاجها وفي أي ظروف صعبة يتم استخدامها.

لا يهم عدد منتجات رغوة البولي يوريثين المطلوبة لصنع عنصر معين، ستستخدم رونغه مواد خام عالية الجودة لتغيير الشكل والأبعاد بدقة لتحقيق مواصفاتك الدقيقة. لدينا خبرة واسعة في تقديم الخدمات لعدة أسواق، مثل تخصيص منتجات رغوة البولي يوريثين، وشريط الإغلاق والتخصيص للمنتجات البلاستيكية وأجزاء المطاط المolded وغيرها. نحن نتطلع إلى التعاون معكم.